Ultraviolet radiation has emerged as one of the most versatile and powerful technologies in modern industry and healthcare. From invisible sterilization processes to precision semiconductor manufacturing, UV technology continues to revolutionize how we approach everything from medical treatments to advanced manufacturing. This comprehensive guide explores the fundamental principles of UV radiation, its classification systems, diverse applications across industries, and the cutting-edge artificial sources that make controlled UV deployment possible.

Introduction to UV Radiation: The Invisible Force in Modern Technology

Understanding Ultraviolet Radiation

Ultraviolet (UV) radiation represents a fascinating segment of the electromagnetic spectrum that sits just beyond visible light. With wavelengths ranging from 100 to 400 nanometers, UV radiation is invisible to the human eye yet plays a crucial role in countless technological applications and natural processes.

The term ultraviolet literally means “beyond violet,” referring to its position beyond the violet end of the visible light spectrum. This non-ionizing radiation is naturally produced by the sun and artificially generated through specialized equipment for various industrial and medical purposes.

Key characteristics of UV radiation include:

- Wavelength range: 100-400 nanometers

- Energy level: Higher than visible light but lower than X-rays

- Penetration ability: Variable depending on wavelength

- Biological effects: Can be both beneficial and harmful

UV radiation’s unique properties make it invaluable across multiple industries. From sterilization and disinfection to advanced manufacturing processes like photolithography, this invisible energy source has revolutionized how we approach everything from healthcare to semiconductor production.

The growing understanding of UV radiation’s potential has led to significant technological advances in recent decades. Industries now harness specific UV wavelengths for precise applications, creating more efficient and effective processes than ever before. This targeted approach allows engineers and scientists to maximize benefits while minimizing unwanted effects, opening new possibilities for innovation in fields ranging from medicine to materials science.

Types of UV Radiation: UV-A, UV-B, and UV-C Classification

The Three Categories of Ultraviolet Radiation

UV radiation is scientifically classified into three distinct categories based on wavelength, each with unique properties and applications. Understanding these classifications is essential for leveraging UV technology effectively.

UV-A Radiation (315-400 nm)

UV-A represents the longest wavelength UV radiation and comprises approximately 95% of UV radiation reaching Earth’s surface. This type penetrates deep into materials and biological tissues, making it valuable for specific applications:

- Phototherapy treatments for skin conditions

- Curing processes in manufacturing

- Black light applications for detection and analysis

UV-B Radiation (280-315 nm)

UV-B radiation carries more energy than UV-A and is partially absorbed by the Earth’s atmosphere. Its medium wavelength makes it particularly useful for:

- Vitamin D synthesis stimulation in medical applications

- Specialized phototherapy treatments

- Research applications requiring moderate penetration

UV-C Radiation (100-280 nm)

UV-C represents the shortest wavelength and highest energy UV radiation. While naturally filtered by Earth’s atmosphere, artificially generated UV-C has become revolutionary in disinfection technology:

- Germicidal applications – destroys bacteria, viruses, and fungi

- Water purification systems

- Air sterilization in healthcare facilities

- Surface disinfection in food processing

Each UV category’s distinct penetration characteristics and energy levels determine their optimal applications. UV-C’s high energy makes it excellent for breaking molecular bonds in pathogens, while UV-A’s deeper penetration suits curing and therapeutic applications. This classification system enables engineers to select the most appropriate UV source for specific technological requirements.

Applications of UV Radiation in Technology and Industry

Diverse Industrial Applications of UV Technology

UV radiation has transformed numerous industries through its unique ability to trigger specific chemical and biological reactions. Modern technological applications span from healthcare to advanced manufacturing, demonstrating the versatility of this invisible energy source.

Disinfection and Sterilization

UV-C radiation has revolutionized sanitization processes across multiple sectors:

- Healthcare facilities: Operating room sterilization and equipment disinfection

- Water treatment plants: Municipal and industrial water purification

- Food processing: Surface sterilization and packaging sanitization

- HVAC systems: Air purification in commercial buildings

The germicidal effectiveness of UV-C stems from its ability to damage DNA and RNA structures in microorganisms, rendering them unable to reproduce or cause infection.

Photolithography and Semiconductor Manufacturing

Advanced manufacturing relies heavily on UV technology for precision processes:

- Microchip fabrication: Creating intricate circuit patterns on silicon wafers

- Printed circuit board production: Precise etching and component placement

- Optical device manufacturing: Lens and mirror coating applications

Medical and Therapeutic Applications

UV radiation serves crucial roles in modern medical treatments:

- Phototherapy: Treating skin conditions like psoriasis and eczema

- Vitamin D therapy: Addressing deficiency-related conditions

- Wound healing: Promoting tissue regeneration and reducing infection risk

- Cancer treatment: Targeted therapy for certain skin cancers

Curing and Polymerization

Industrial UV curing processes offer significant advantages:

- Instant curing: Immediate hardening of coatings and adhesives

- Energy efficiency: Lower power consumption than thermal curing

- Precision control: Exact timing and intensity management

- Environmental benefits: Reduced volatile organic compound emissions

These applications demonstrate UV technology’s transformative impact across industries, enabling faster, more efficient, and environmentally friendly processes.

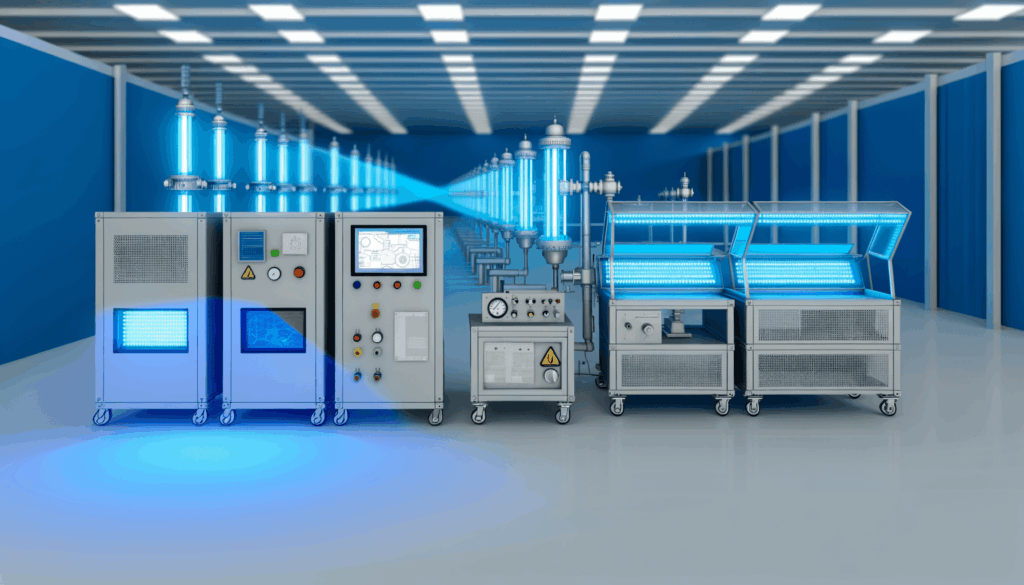

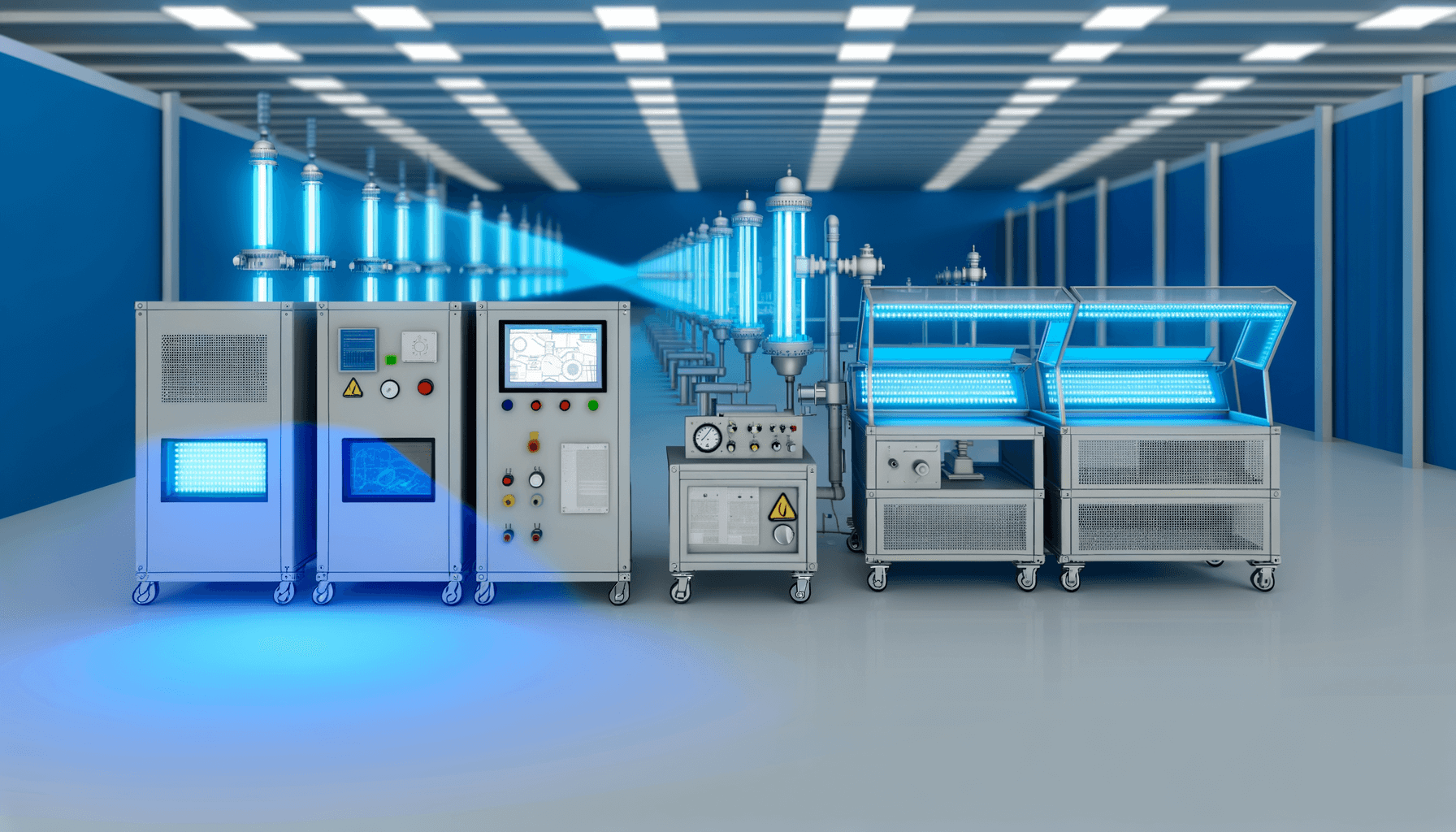

Artificial UV Sources: Engineering Controlled Radiation

Technologies for Generating Artificial UV Radiation

While the sun remains the primary natural source of UV radiation, artificial UV generation has become essential for controlled industrial and medical applications. Modern engineering has developed sophisticated systems to produce specific UV wavelengths with precise intensity and timing.

Traditional UV Sources

Mercury vapor lamps have long been the standard for industrial UV generation:

- High-pressure mercury lamps: Broad spectrum output for general applications

- Low-pressure mercury lamps: Primarily UV-C emission for germicidal use

- Medium-pressure systems: Balanced output across UV spectrum

These systems offer reliable performance but require warm-up time and contain mercury, presenting environmental considerations.

LED UV Technology Revolution

UV LED systems represent the next generation of artificial UV sources:

- Instant operation: No warm-up time required

- Precise wavelength control: Specific nanometer targeting

- Energy efficiency: Up to 50% more efficient than traditional sources

- Compact design: Smaller footprint and flexible installation

- Environmental safety: Mercury-free operation

Excimer Lamps and Specialized Sources

Advanced UV technologies serve specialized applications:

- Excimer lamps: Ultra-narrow wavelength bands for research

- Plasma sources: High-intensity applications

- Lasers: Precise beam control for microfabrication

Controlling UV Output

Modern UV systems incorporate sophisticated controls:

- Intensity modulation: Variable power output

- Pulsed operation: Precise timing control

- Wavelength selection: Multi-source systems

- Safety interlocks: Automated protection systems

The evolution toward LED-based UV sources continues to drive innovation, offering unprecedented control over UV radiation characteristics while reducing operational costs and environmental impact.

This technological advancement enables new applications previously impossible with traditional sources.

UV radiation technology represents a cornerstone of modern industrial and medical innovation, with applications spanning from life-saving disinfection systems to precision semiconductor manufacturing. As artificial UV sources continue to evolve—particularly with the advancement of LED technology—we can expect even more precise, efficient, and environmentally friendly UV applications to emerge. The future of UV technology lies in enhanced control systems, improved energy efficiency, and expanded applications across emerging industries, making ultraviolet radiation an increasingly vital tool in our technological arsenal.